Why Industrial Robotics Training ?

Humans are not Work at high temperature, heavy welding application, high manufacturing and Can’t do multiple task at time same time. But INDUSTRIAL ROBOTS are do that. They can be programmed to perform dangerous, dirty and repetitive task with consistent precision and accuracy. Industrial Robots are used in a variety of industries and applications. They come in a wide range of models with the reach distance, payload capacity and the number of axes.

What We Do ?

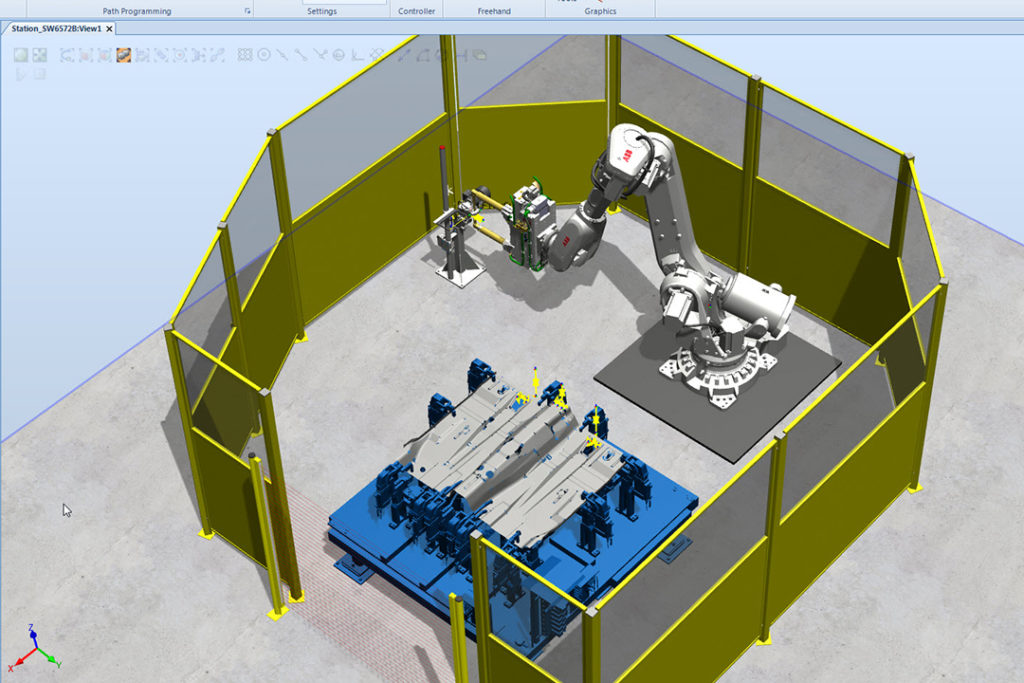

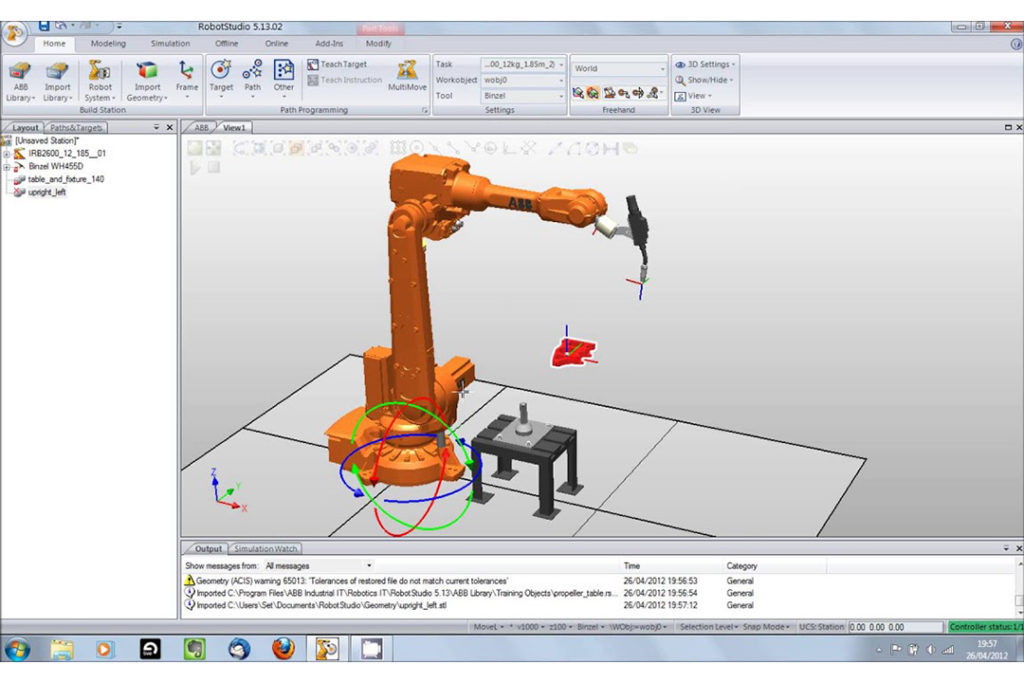

IOLOGIX gives you a different types of INDUSTRIAL ROBOTICS applications with basics and advance level Training. We provides a multiple process applications which is used in Manufacturing/Assembly industries and we have ABB robot, NACHI robot, KUKA robot and UNIVERSAL robot through Simulations.

Fully Equipped Updated Software and Hardware facility

Individual Focus

Industrial experienced faculties

Career Guidance & Mentorship

100% Placement Assistance

Industrial Robotics Training Modules

Basic Level

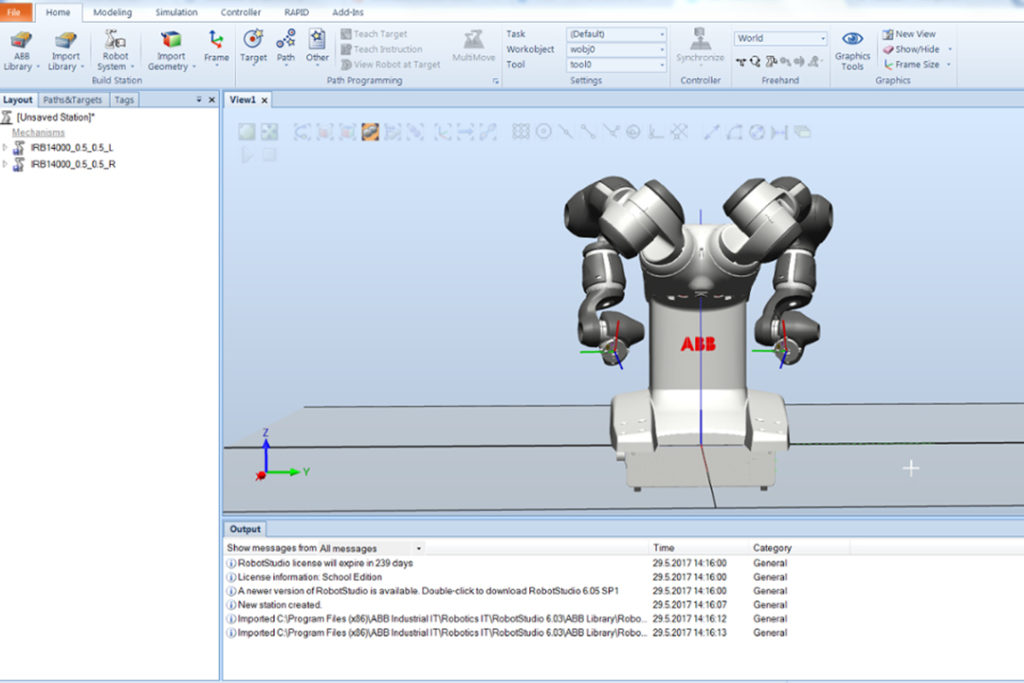

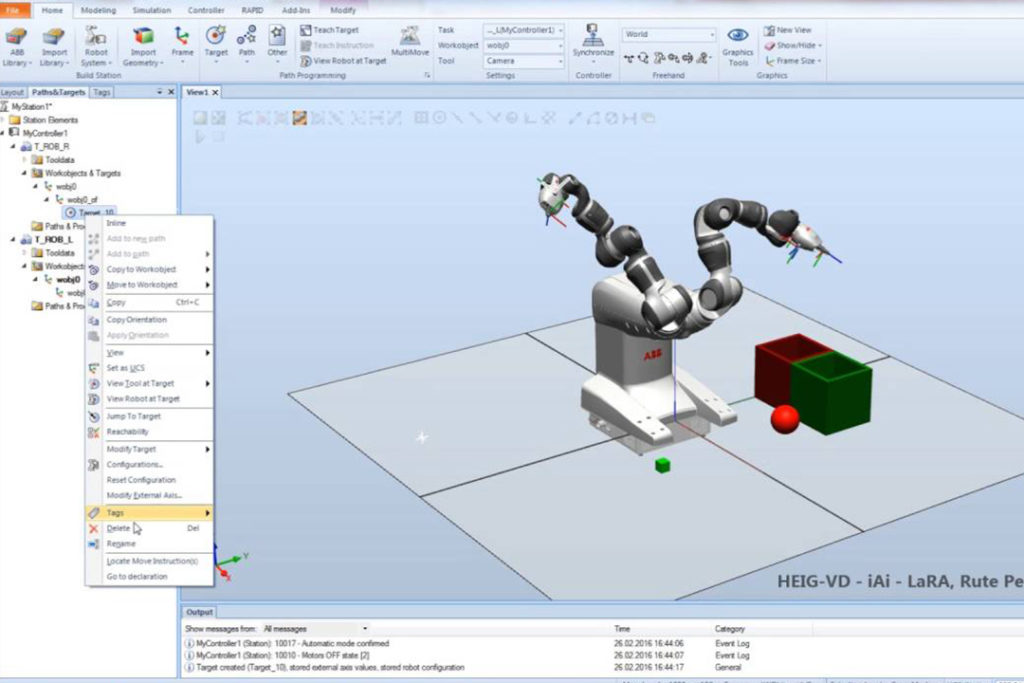

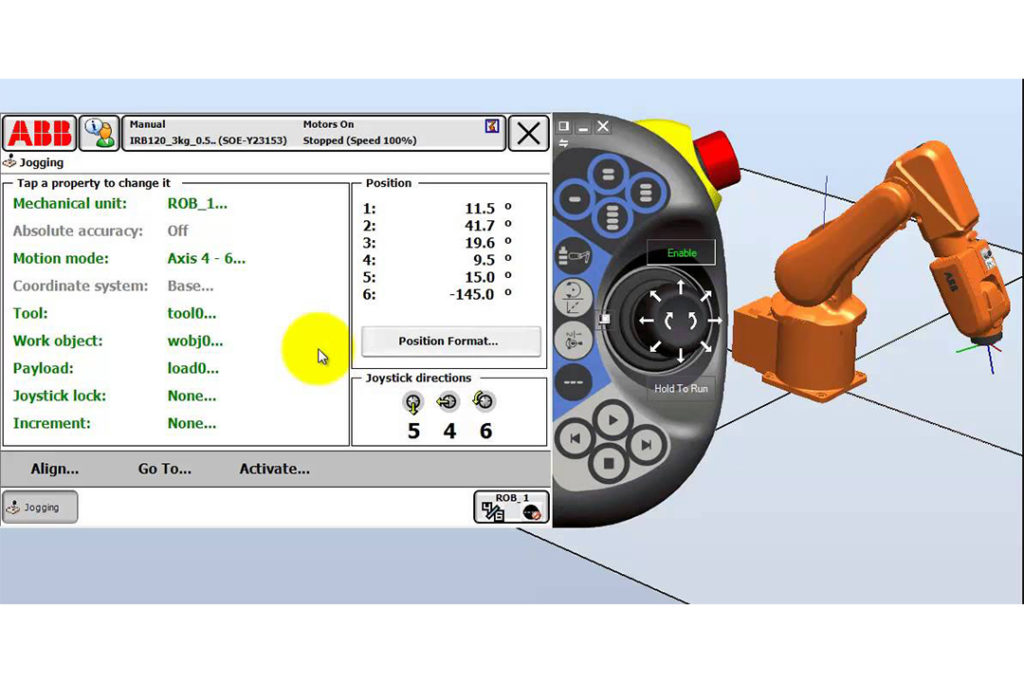

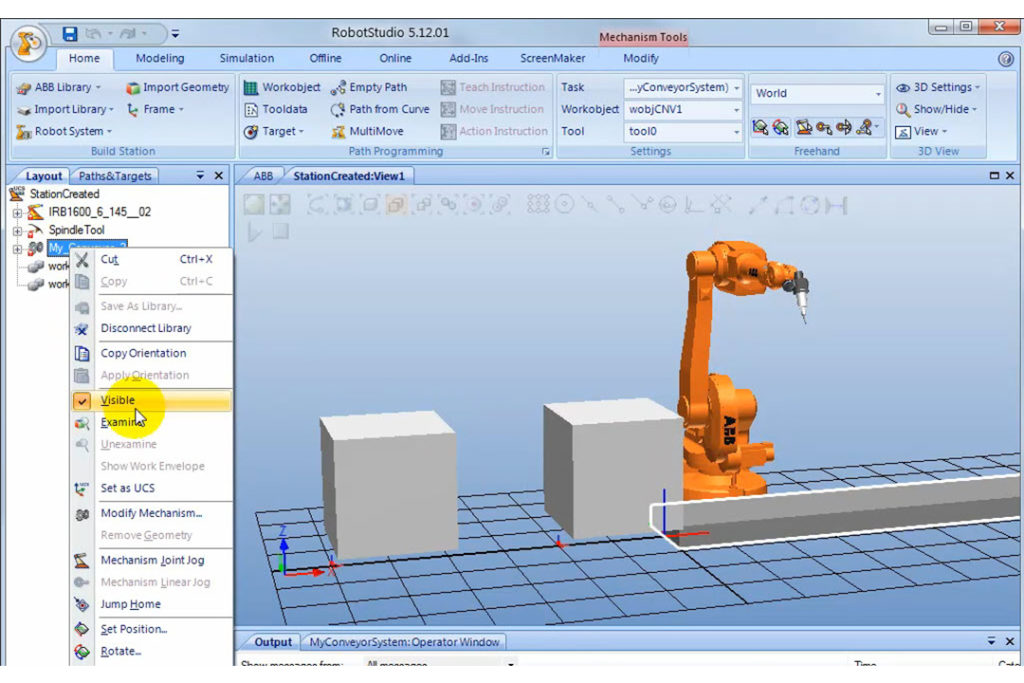

The aim of this training is to acquaint the participants with basic concept of programming of the ABB robot system. This includes safety instructions for ABB robots, Knowledge and usage of the coordinate systems, Methods of tool calibration and tool payload, basic concepts of robot programming, operation of robot system and Robot Simulation on RobotStudio software.

Advance Level

Building on the Basic level training, Robot Programming is extended and covered in great detail and depth. The main emphasis of this training module is on the high level programming language ARLA and on the structuring and documentation of Robot Programs.

Expert Level

The Expert Robot Programming is aimed at the programming personnel for ABB industrial robots. Building on the “Advanced Robot Programming” training, programming knowledge and skills are further extended and covered in depth. Robotic project execution and interrupt programming implementing complex tasks as structured robot programs is done using the high-level programming language ARLA.

INDUSTRIAL AUTOMATION TRAINING PACKAGES

-

ADVANCED INDUSTRIAL AUTOMATION ENGINEER

COURSE CONTENT

- Field Instruments

- Electric Control Panel Wiring

- 5 Brands of PLC (Allen-Bradley, Omron, Mitsubishi, Siemens 200 smart, Delta)

- 1 Brands of SCADA (Delta)

- 2 Brands of HMI (Delta, Omron)

- 1 Brand of VFD ( Schneider )

DURATION

» Fast Track : 15 days

» Normal Track : 30 days

» Eligibility : BE /ME/DIPLOMA EEE,ECE, MECH, E&I, ICE, ROBOTICS AND AUTOMATION, MECHTRONICS

-

MASTER DIPLOMA IN ADVANCED INDUSTRIAL AUTOMATION ENGINEER

COURSE CONTENT

- Field Insruments

- Electric Control Panel Wiring

- 6 Brands of PLC (Allen-Bradley, Omron, Mitsubishi, Siemens 200 smart, Delta, Siemens-1200)

- 2 Brands of SCADA (Delta, Siemens-1200)

- 3 Brands of HMI (Delta, Omron, Siemens-1200)

- 1 Brand of VFD ( Schneider )

- 1 Brand of DCS ( ABB )

- Pneumatics Concepts

- Encoder

- Communication Protocols

- PID Controllers

DURATION

» Fast Track : 30 days

» Normal Track : 45 days

»Eligibility : BE /ME/DIPLOMA EEE,ECE, MECH, E&I, ICE, ROBOTICS AND AUTOMATION, MECHTRONICS

-

POST GRADUATION DIPOLMA IN INDUSTRIAL AUTOMATION ENGINEER

COURSE CONTENT

- Field Insruments

- Electric Control Panel Wiring

- 8 Brands of PLC (Allen-Bradley, Omron, Mitsubishi- F Series & Q Series, Siemens 200 smart, Delta, Siemens-1200, Schneider)

- 3 Brands of SCADA (Delta, Siemens-1200, Intouch)

- 3 Brands of HMI (Delta, Omron, Siemens-1200)

- 1 Brand of VFD ( Schneider )

- 1 Brand of DCS ( ABB )

- Pneumatics Concepts

- Encoder

- Communication Protocols

- PID Controllers

- Servo Motor

- Real Time Applications

DURATION

» Fast Track : 45 days

» Normal Track : 60 days

» Eligibility : BE /ME/DIPLOMA EEE,ECE, MECH, E&I, ICE, ROBOTICS AND AUTOMATION, MECHTRONICS

-

ADVANCED DIPLOMA IN INDUSTRIAL INTERNET OF THINGS ENGINEER

COURSE CONTENT

- Field Insruments

- Electric Control Panel Wiring

- 2 Brands of PLC (Allen-Bradley /Mitsubishi / Delta / Siemens-1200)

- 1 Brands of SCADA ( Siemens-1200 )

- 3 Brands of HMI ( Siemens-1200 )

- Node-red

- Embedded Controller

- MQTT

- Amazon AWS IOT Care

- Communication Protocols

- PID Controllers

- Internet Of Things

DURATION

» Fast Track : 45 days

» Normal Track : 60 days

»Eligibility : BE /ME/DIPLOMA EEE,ECE, MECH, E&I, ICE, ROBOTICS AND AUTOMATION, MECHTRONICS

-

ADVANCED INDUSTRIAL AUTOMATION LABVIEW ENGINEER

COURSE CONTENT

- Field Insruments

- Electric Control Panel Wiring

- 2 Brands of PLC (Allen-Bradley / Mitsubishi / Delta / Siemens-1200)

- 2 Brands of HMI (Delta / Siemens)

- 1 Brand of VFD ( Schneider )

- Data Login

- Real Time Application

- PLC to Labview Interface

- Communication Protocol ( RS232, RS485, TCP/IP, UDP)

DURATION

» Fast Track : 45 days

» Normal Track : 60 days

» Eligibility : BE /ME/DIPLOMA EEE,ECE, MECH, E&I, ICE, ROBOTICS AND AUTOMATION, MECHTRONICS

-

SIEMENS LAB

COURSE CONTENT

- Field Insruments

- Electric Control Panel Wiring

- Siemens 1200 /300 PLC

- Siemens HMI

- Siemens Scada

- Communication Protocol

- RS232 (Barcode Scanner, Load cell)

- RS485 (Modbus, Temperature, VFD)

- TCP / IP

- UDP

- Servo

- Encoder

- PID controller

DURATION

» Fast Track

» Normal Track

-

CUSTOMISED

MITSUBISHI LAB TRAINIING

- Field Instruments

- Electric Control Panel Wiring

- Mitsubishi Q-series/ F-series

- Mitsubishi HMI

- Communication Protocol

- RS232 (Barcode Scanner, Load cell)

- RS485 (Modbus, Temperature, VFD)

- TCP / IP

- UDP

- Servo

- Encoder

- PID Controller

DELTA & OMRON LAB TRAINIING

- Field Instruments

- Electric Control Panel Wiring

- Delta EX2/SA

- Delta HMI

- Delta SCADA

- Omron CP1E

- Omron HMI

- Communication Protocol

- RS232 (Barcode Scanner, Load cell)

- RS485 (Modbus, Temperature, VFD)

- TCP / IP

- UDP

- Servo

- Encoder

- PID Controller

ROCKWELL LAB TRAINIING

- Field Instruments

- Electric Control Panel Wiring

- Micrologix 1400/ Compactlogix

- Allen Bradley HMI

- Allen Bradley SCADA

- Communication Protocol

- RS232 (Barcode Scanner, Load cell)

- RS485 (Modbus, Temperature, VFD)

- TCP / IP

- UDP

- Servo

- Encoder

- PID Controller

IOT LAB TRAINIING

- Field Instruments

- Electric Control Panel Wiring

- 2 Brands of PLC(Allen-Bradley/ Mitsubishi/ Delta/ Siemens1200)

- 1 Brand of SCADA

- 1 Brand of HMI

- Communication Protocol

- Node-Red

- Embedded Controller

- MQTT

- Amazon AWS IOT care

- Internet of Things

- PID Controller